What’s MES?

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output. MES works in real time to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services).

Benefits

Manufacturing Execution Systems create flawless manufacturing processes and provide real-time feedback of requirement changes”, and provide information at a single source. Other benefits from successful MES implementation might include:

- Reduced waste, re-work and scrap, including quicker setup times.

- More accurate capture of cost-information (e.g. labor, scrap, downtime, and tooling)

- Increased uptime

- Incorporate paperless workflow activities

- Manufacturing operations traceability

- Decreases downtime and easy fault finding

- Reduced inventory, through the eradication of just-in-case inventory

(Source; Wikipedia)

What can we do?

Our expertise about MES systems are;

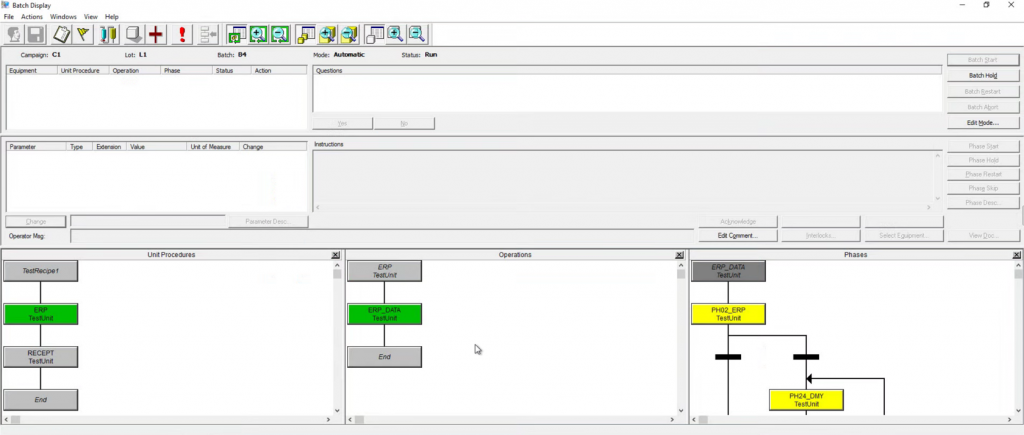

Implementing the high flexible batching processes consistent with the ISA-88 standard.

THE CONTROL SYSTEM INDEPENDENT BATCH MANAGEMENT SOFTWARE AUTOMATES BATCH PROCESSES.

Support for MES and production IT systems

WITH YEARS OF EXPERIENCE WE CAN SUPPORT/MAINTAIN MES SYSTEM THAT IS ALREADY IMPLEMENTED

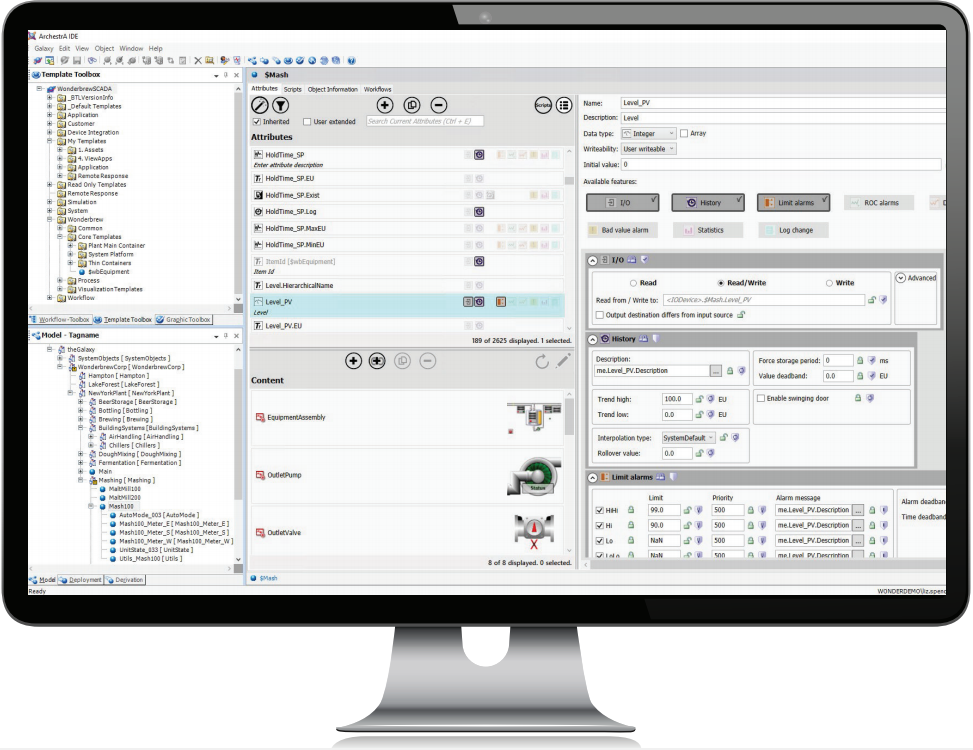

Upgrading AVEVA(FORMERLY Wonderware) System Platform and Inbatch system

WE ARE EXPERIENCED ABOUT UPGRADING THE AVEVA CONTROL SYSTEM (FORMERLY SCHNEDIER ELECTRIC SOFTWARE) SOFTWARES. FOR EXAMPLE SYSTEM PLATFORM, InTouch, HISTORIAN and HISTORIAN CLIENT, BATCH MANAGEMENT(FORMERLY InBatch) AND BATCH CLIENT.

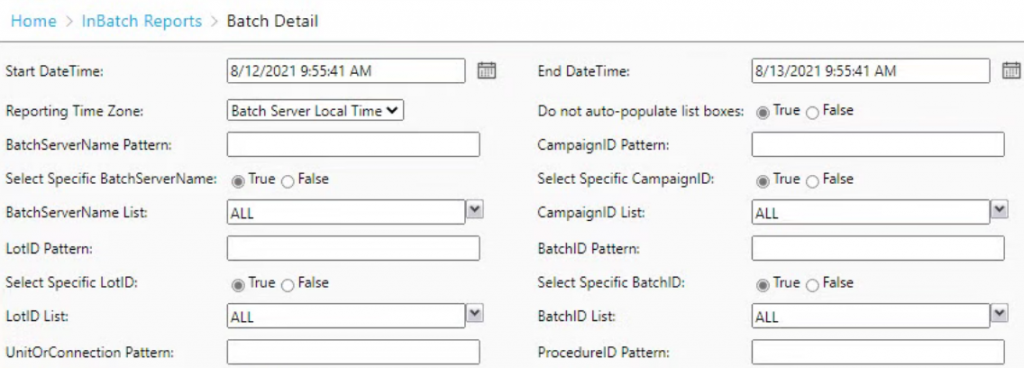

User defined batch reports that can accessible from web browser.

Converting reports from Crystal Reports to MS SQL Reporting Services.

Consultant and project member for implementing a Production and Information Management System for comparing efficiency across multiple sites and across different process plants in the food and beverage industry.

Participating in Analyzing and integrating laboratory-instruments into ERP-systems

Who do we work with?

We work for large sized companies such as ArlaFoods and PPG/Dyrup.